A fluorene derivative of high purity is produced by reacting fluorenone with phenoxyethanol in the presence of a sulfuric acid-thiol catalyst system, dissolving the reaction mixture in a lower aliphatic alcohol and adding water to the resulting solution for precipitation of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene [fluorene derivative]. A fluorene derivative of still higher purity is obtained by recrystallization from a lower aliphatic alcohol.

In accordance with this invention, a fluorene derivative can be produced advantageously on a commercial scale without incurring any appreciable loss of fluorenone, in good yield, with high efficiency and in a reduced production time.

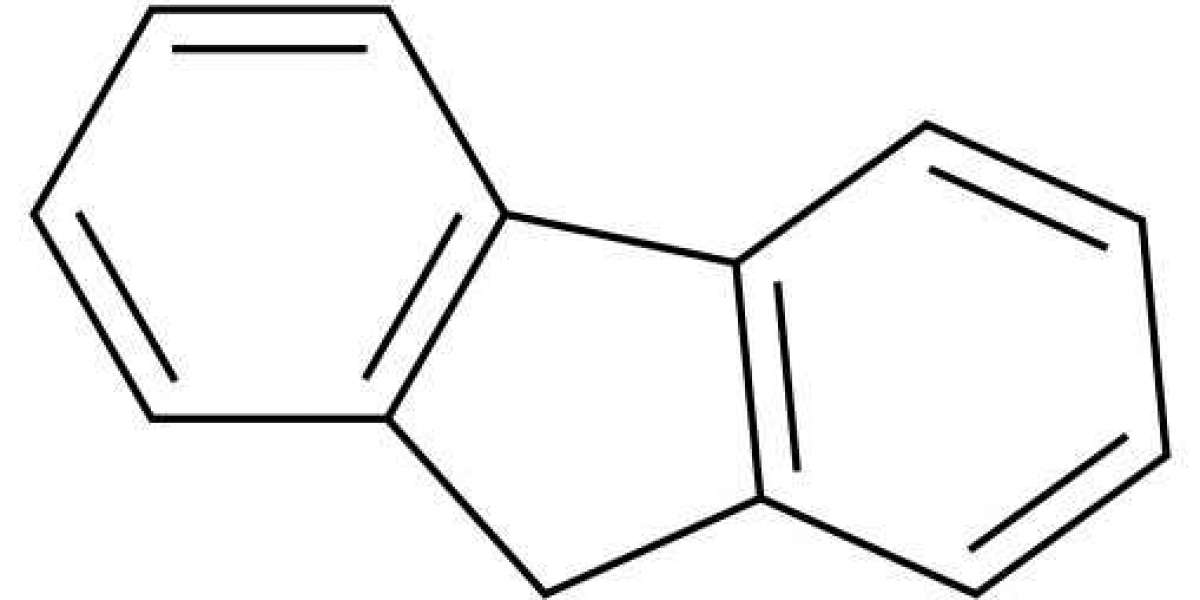

It is known that 9,9-bis(4-hydroxyphenyl)fluorene can be synthesized by condensation reaction of fluorenone, as obtained by air oxidation of fluorene in liquid phase, and phenol in the presence of hydrogen chloride-mercaptopropionic acid [J. Appl. Polym. Sci., 27 (9), 3289, 1982] and that 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene can also be synthesized by subjecting 9,9-bis(4-hydroxyphenyl)fluorene and ethylene oxide to addition reaction.

However, the above prior art technology starting with fluorenone for the production of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene comprises two production processes.

Thus, the prior art technology not only requires the ultimate isolation and purification of the objective compound 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene but also requires the separation and purification of the intermediate compound 9,9-bis(4-hydroxyphenyl)fluorene with the associated treatment of unreacted phenol and hydrogen chloride gas in the first process and the treatment of unreacted ethylene oxide in the second process.

The above prior art technology, thus, involves a large number of steps and is, therefore, commercially disadvantageous in terms of production efficiency. Furthermore, the technology involves the use of ethylene oxide which is liable to polymerize chemically, so that the final product tends to contain ethylene oxide polymers.