Fridge fins are the vital components of any refrigerator. Without them, refrigerators would be unable to perform their basic functions. As such, their design is essential for optimizing refrigeration performance. In this blog post, we will discuss the design of refrigerator fins and how it affects their performance. We’ll also explore the various factors that must be taken into account when designing fridge fins, from material selection to heat transfer properties. Armed with this knowledge, you’ll have a better understanding of how to optimize your refrigerator design for maximum efficiency.

The different types of fins

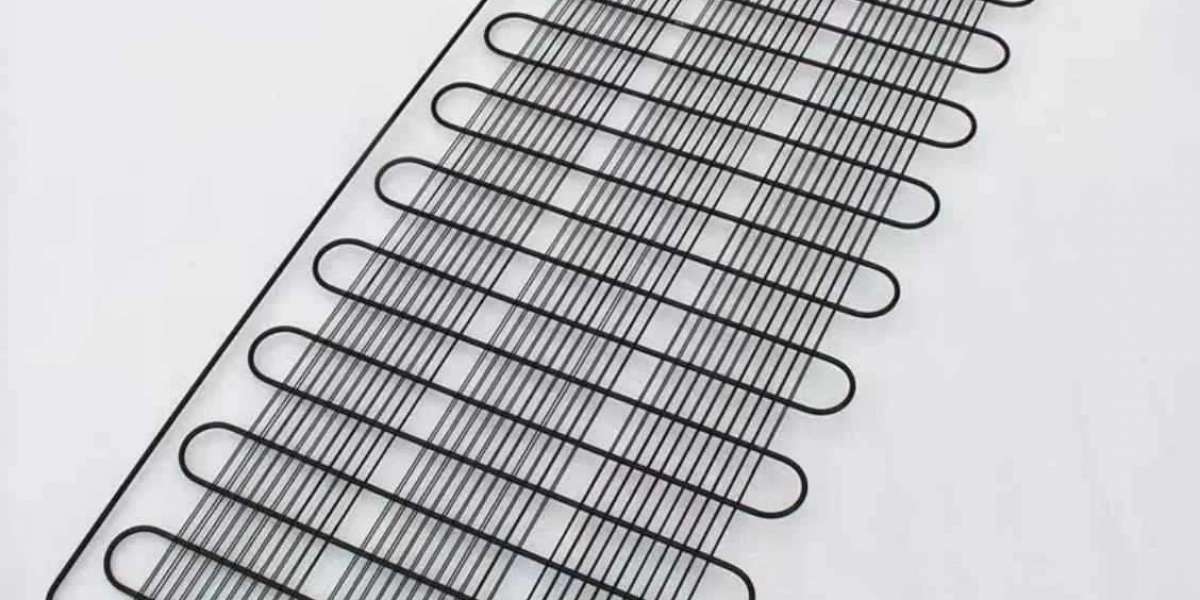

There are many different types of fins used in refrigerator design. The most common type is the flat plate fin, which is a simple metal plate with a series of parallel fins attached to it. These fins increase the surface area of the plate, which helps to improve heat transfer.

Another type of fin is the Louver fin, which is similar to a flat plate fin but has a series of vertical slots cut into it. These slots help to increase air flow over the surface of the fin, which helps to improve heat transfer.

A third type of fin is the herringbone fin, which is a series of zig-zag shaped fins that are arranged in a herringbone pattern. This pattern helps to increase air flow over the surface of the fin and also helps to reduce pressure drop.

Finally, there is the corrugated fin, which is a series of parallel fins that are connected together with corrugations. These corrugations help to increase air flow over the surface of the fin and also help to reduce pressure drop.

The material of the refrigerator fins

Refrigerator fins are made of materials that are good at absorbing heat and transferring it to the surrounding air. The most common material used for refrigerator fins is aluminum. Aluminum is a good conductor of heat and has a high thermal conductivity. Other materials that can be used for refrigerator fins include copper, brass, and stainless steel.

How to design refrigerator fins

When it comes to the design of refrigerator fins, there are a few things that you will need to take into account. The first is the material that you will be using. The most common materials used for refrigerator fins are aluminum and copper. However, other materials such as stainless steel and brass can also be used.

The next thing to consider is the thickness of the material. The thicker the material, the more heat it will be able to dissipate. However, thicker materials are also more difficult to work with and may require special tools.

Finally, you will need to decide on the shape of the fins. There are a variety of shapes that can be used, but the most common are rectangular and triangular. Once you have decided on the shape of the fins, you can then start to add them to your design.

Refrigerator fins supplier - Bodu

Dongtai Bodu Refrigeration Equipment Co., Ltd. was established in June 2012, mainly engaged in the research and development and production of refrigerators, freezers, water dispensers, shutter-type condensers, wire-tube evaporators and filter drier products. The company has been committed to the innovation and development of new technologies in the dry refrigeration industry, adhered to the road of technological innovation, and used the new design of wire tube condensers to replace high-cost copper tube condensers. Under the new form of low-carbon and environmental protection, the company has developed a new Compact, high-efficiency, product with high salt spray resistance, wire tube condenser for carbon dioxide and R290 media, design and optimize new products for customers, and promote industry development trends.

Related News about Refrigerator Fins

Why commercial freezer condenser popular?