Since the advent of 3D printing, a sizeable number of people have, for a sizeable amount of time, been debating whether or not 3D printing will eventually replace CNC processing, sheet metal manufacturing, and other processes. This discussion has been going on for quite some time. This discussion has been going on for a considerable amount of time. In point of fact, it is a possibility that is extremely improbable, at the very least for a significant amount of time to come after this point. According to the current trend in technological development, additive manufacturing, which is also known as 3D printing, has become an effective combination with computer numerical control (CNC) processing and sheet metal manufacturing. This is indicated by the fact that online cnc machining service the pattern of technological advancement has recently shifted.

The processing of sheet metal is extremely helpful in a wide variety of industries, including but not limited to the medical field, the automotive industry, the telecommunications industry, and the production of electrical and electronic goods. Sheet metal is used in the construction of the product's skeleton, which can be found in an automobile, a computer, or a mobile phone, for example. It not only provides support but also makes a contribution to the product's overall shape. The phase of the process of developing new products that entails the design and production of components made of sheet metal is becoming an increasingly important step. This phase involves the design and production of the aforementioned components. The method of manufacturing a diverse range of products in relatively modest quantities is rapidly becoming an extremely common practice.

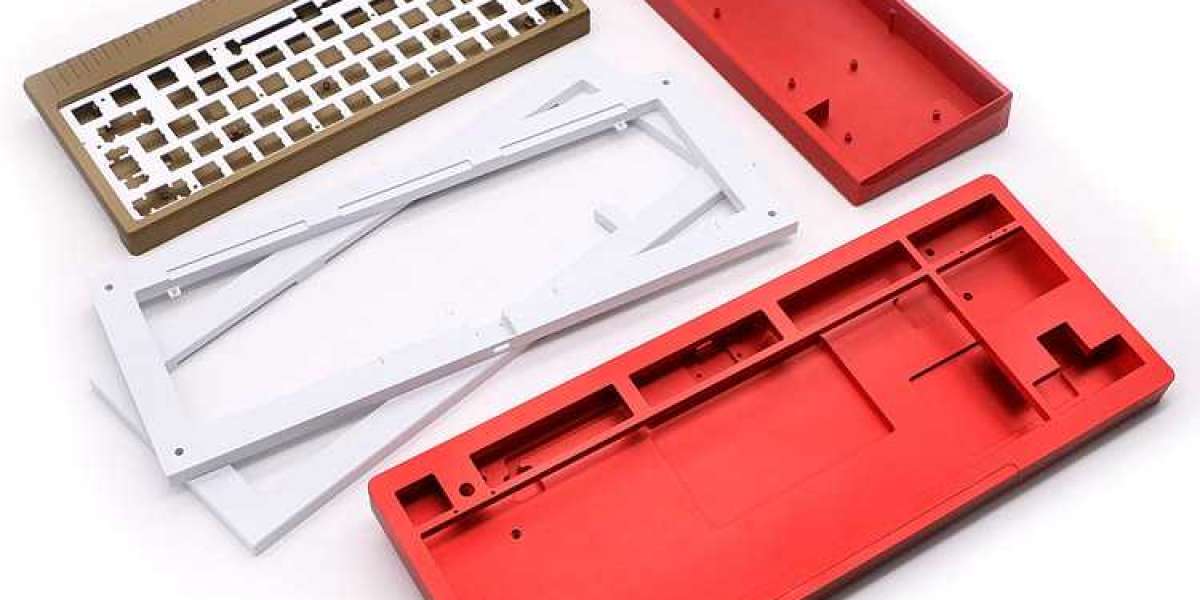

Molds of various kinds are used extensively throughout the process of fabricating sheet metal, which involves the use of a large number of molds. This is because the process involves the use of a large number of molds. As an illustration, the production of automobile sheet metal parts makes use of a wide variety of molds. Some of these molds include punching dies, cutting dies, forming dies, separating dies, stamping dies, and bending punches. Other molds include stamping dies, bending punches, and separating dies. Because of this, it is not at all suitable for the production of sheet metal components in low quantities. This is because of the direct result of this. This method is ideal for the rapid production of plates with simple structures because it does not require molds, it is cost-effective, it has a short cycle, and it is suitable for mass production. On the other hand, due to the fact that it is unable to shape the sheet metal in the appropriate manner, this method is unable to produce certain components made from sheet metal that have specially shaped profiles. A domestic car seat manufacturing company had one week to create a set of newly designed seat samples after they received the order; however, the molds that would be used to support the samples were still in the process of being manufactured. The second group of seats is made up of 78 individual pieces and has a thickness that varies from 1. 5 millimeters; the vast majority of these pieces feature ribs and protrusions on them. As a direct consequence of this, the utilization of CNC machining is not a choice that ought to be taken into consideration.

As a direct consequence of this, they arrived at the verdict that they ought to make use of three-dimensional printing. In a different application of the technology, the thickness of the outer shell was calculated to be 73 millimeters, while the thickness of the middle structural area was measured to be 0. 6 millimeters throughout its entirety. Sheet metal is used for the structure of these four parts so that the wall thickness can be kept to a minimum. In addition, the design of the structure is intricate, and it is not possible to fabricate it by milling the metal, cutting and bending the metal, or any combination of these methods. Stamping and three-dimensional printing are the only two options that can be chosen from because there are no other choices available. The processing of parts is experiencing a rise in demand for variety as well as for small batches as a direct result of the increasingly diverse nature of the products that are available today. This demand for variety and for small batches is expected to continue. This is a direct consequence of the increased demand for products that are produced in small batch sizes.

It has come to our attention that this particular sector is the one order cnc machined parts that stands to gain the most from the application report on 3D printing.

Since it was first developed in the 1980s, people have been making use of a technology known as 3D printing. Now that it is an accepted component of our everyday lives, 3D printing makes our lives and the work that we do easier in every facet, including the fields of education, medical care, and even advanced manufacturing for the aerospace industry. Printing in three dimensions online cnc machining service is becoming increasingly common.

1. Bring the quantity of stock that is currently available down to a lower level.On the other hand, due to the fact that there are so many different kinds of auto parts, it is impossible to keep a stock of each and every one of them individually.As a direct result of this, the expenses that are connected with the upkeep of inventory will continue to be high, and the fact that there is a greater number of small manufacturers competing in the market means that upkeep will take longer.Because online cnc machining service of this, a new subcategory of spare parts has emerged; it is known as components made using 3D printing, and its existence can be attributed to the aforementioned reason.Because stores can print the necessary parts right there on the premises, it is possible to alleviate the strain placed on inventory and cut down on the amount of time spent on maintenance. This is made possible by the fact that stores are able to print their own parts.Eliminating molds and cutting down on waste is among the goals of this project.

When compared to other, more conventional methods of production, 3D printing does not require the creation of molds in advance, and the finished product can be obtained without the need to go through the laborious processes of forging. This is in contrast to other, more conventional methods of production.This stands in stark contrast to some of the other, more conventional production methods.A sizeable portion of the waste that would ordinarily be thrown away as part of the manufacturing process is instead left in place.As a natural consequence, this leads to decreased costs associated with both the tooling and the scrap.It is common knowledge that it takes a traditional manufacturer approximately five years from the time they decide to produce a car until they see their first finished product after making the decision to produce the vehicle. This time period begins when the manufacturer makes the decision to produce the vehicle.

3. Make use of a system that allows for production to be carried out in a distributed fashion

It is absolutely necessary for the automotive industry to have centralized production, assembly, and molding facilities.This is because the automotive industry is a highly concentrated sector, which is the primary reason for this trend.In order to make the connection in terms of transportation, a significant investment of one's time as well as one's resources is required.For instance, the brand-new Citroen automobile is manufactured in Chengdu before it is exported to the markets of other countries all over the world.The technology that underpins 3D printing will, of course, need to advance in the direction of higher printing quality as well as faster printing speeds in order to make this a reality.