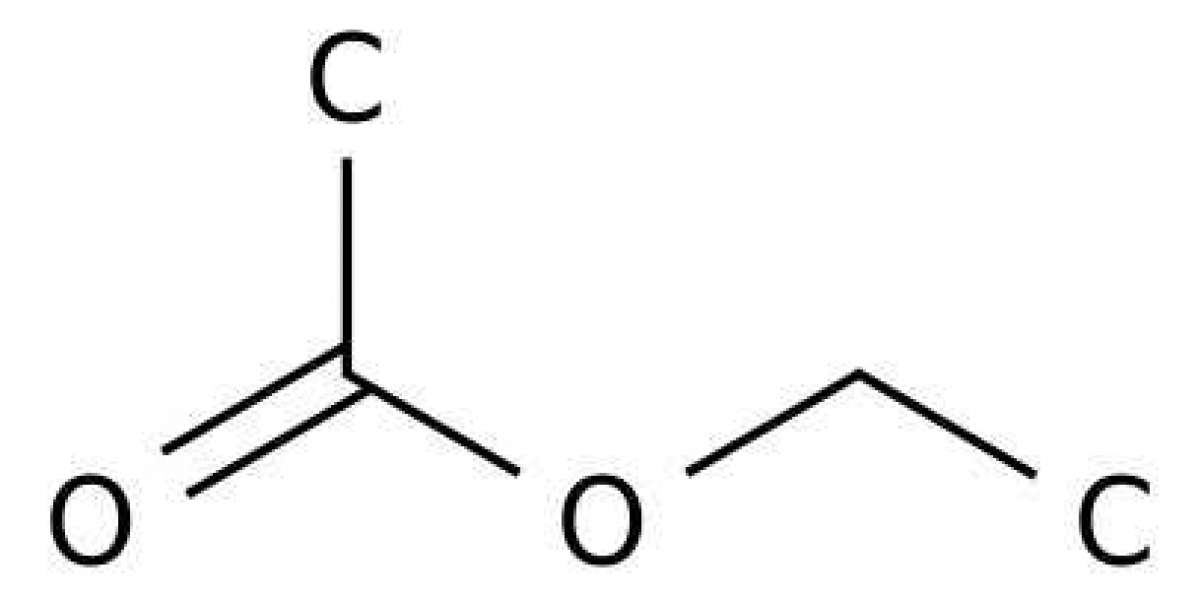

Ethyl acetate is readily absorbed following oral, dermal, or inhalation exposures. It is rapidly hydrolyzed to ethanol and acetic acid prior to absorption in the gastrointestinal tract following oral administration, and in the upper respiratory tract following inhalation exposure.

Distribution

Absorbed ethyl acetate molecular weight is also quickly hydrolyzed in blood to ethanol and acetate. Blood concentrations of ethanol can increase if the production of ethanol, following absorption and hydrolysis of ethyl acetate, exceeds metabolism and elimination of ethanol.

Ethyl acetate is rapidly hydrolyzed to ethanol and acetic acid. When ethyl acetate molecular weight was injected intraperitoneal at 1.6 g kg−1, hydrolysis to acetic acid and ethanol occurred rapidly. The biological half-life value of the conversion of ethyl acetate molecular weight to ethanol was found to be between 5 and 10 min. At doses higher than 1.6 g kg−1 in rats the rate of hydrolysis exceeded the ethanol oxidation leading to the ethanol accumulation in the vascular system.

Ethyl acetate is a solvent found in nature and is environmentally safe and acceptable for food applications. For instance, it is used in the packaging industry because it provides high printing resolution on plastics and metals. D-Limonene is a major compound found in oil extracted from citrus and is present in orange and fruit juices. It is also used in cleaning products as a solvent or a water dilutable product. It is a very versatile chemical and therefore used in a wide variety of applications. Scalping of D-limonene from citrus juices can lead to loss of citrus flavor. Determination of the barrier properties of plastics to these organic compounds is very important in industrial applications.

In fact, there are several ethyl acetate molecular weight production technology alternatives. Traditionally, ethyl acetate has been manufactured from fossil-based resources but in terms of sustainability, recent research efforts have focused in the investigation of a possibility of a simple and economical one-pot synthesis strategy, taking advantage of bioethanol. The main fossil-based process comprises the esterification reaction between ethanol and acetic acid. In this process, ethanol is produced by hydration of ethylene and acetic acid by methanol carbonylation reaction. The process is known to be acid catalyzed and liquid sulfuric acid is a commonly used in the reaction. As mentioned earlier, liquid acids are not anymore suitable due to tightening environmental requirements and difficult handling problems. As a result, some researches have demonstrated the process over solid acid catalysts such as zeolites, aluminum sulfates, and heteropolyacid-supported montmorillonites. Additionally, some other ways to produce ethyl ethanoate comprise the so-called Tishchenko reaction between two acetaldehyde molecules, liquid-phase oxidation of n-butane, copolymerization of butyraldehyde and polyvinyl acetate, and esterification of acetic acid and ethylene.

The simple ethanol and aqueous ethanol-based process to ethyl acetate is the most important approach today. It is also worth mentioning that the possibility to carry out the reaction without any additional reagents and nonfossil-based feedstocks is a clear benefit. Based on the research activity in this field, several studies demonstrate the process quite comprehensively. It is generally known that ethanol valorization to ethyl ethanoate can proceed via two pathways which are known as the dehydrogenative and the oxidative process. The difference between these two options is related to the use or absence of oxygen in the reaction. Additionally, the oxidative route is rarely reported in the scientific literature but the main advantage is the straightforward and, thus, an economically feasible acetate purification process. On the other hand, the ethanol-to-air ratio should be kept at low levels due to the explosive nature of the mixture.